3D Soft Serve Ice Cream Cone Kit

3D Soft Serve Ice Cream Cone Kit

Couldn't load pickup availability

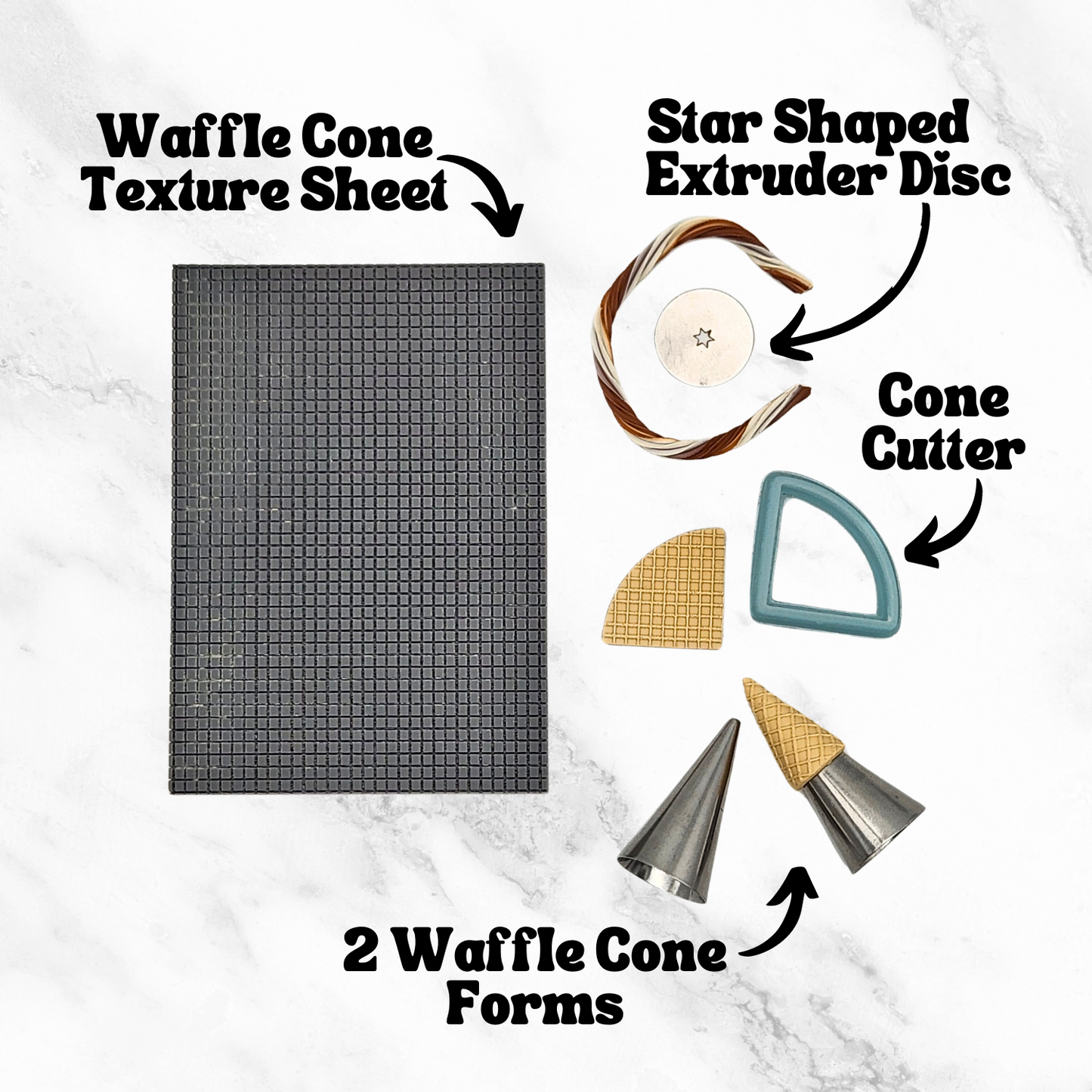

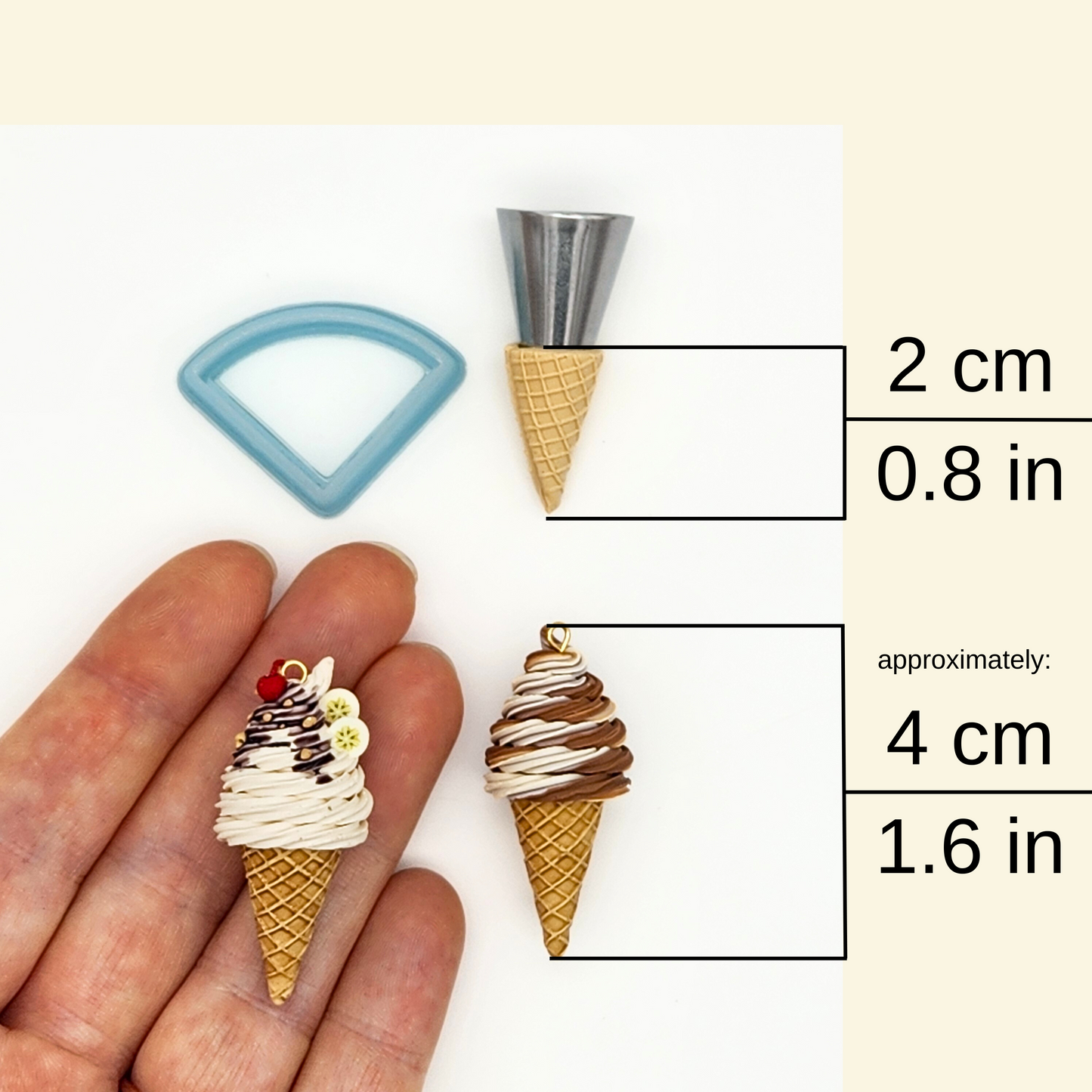

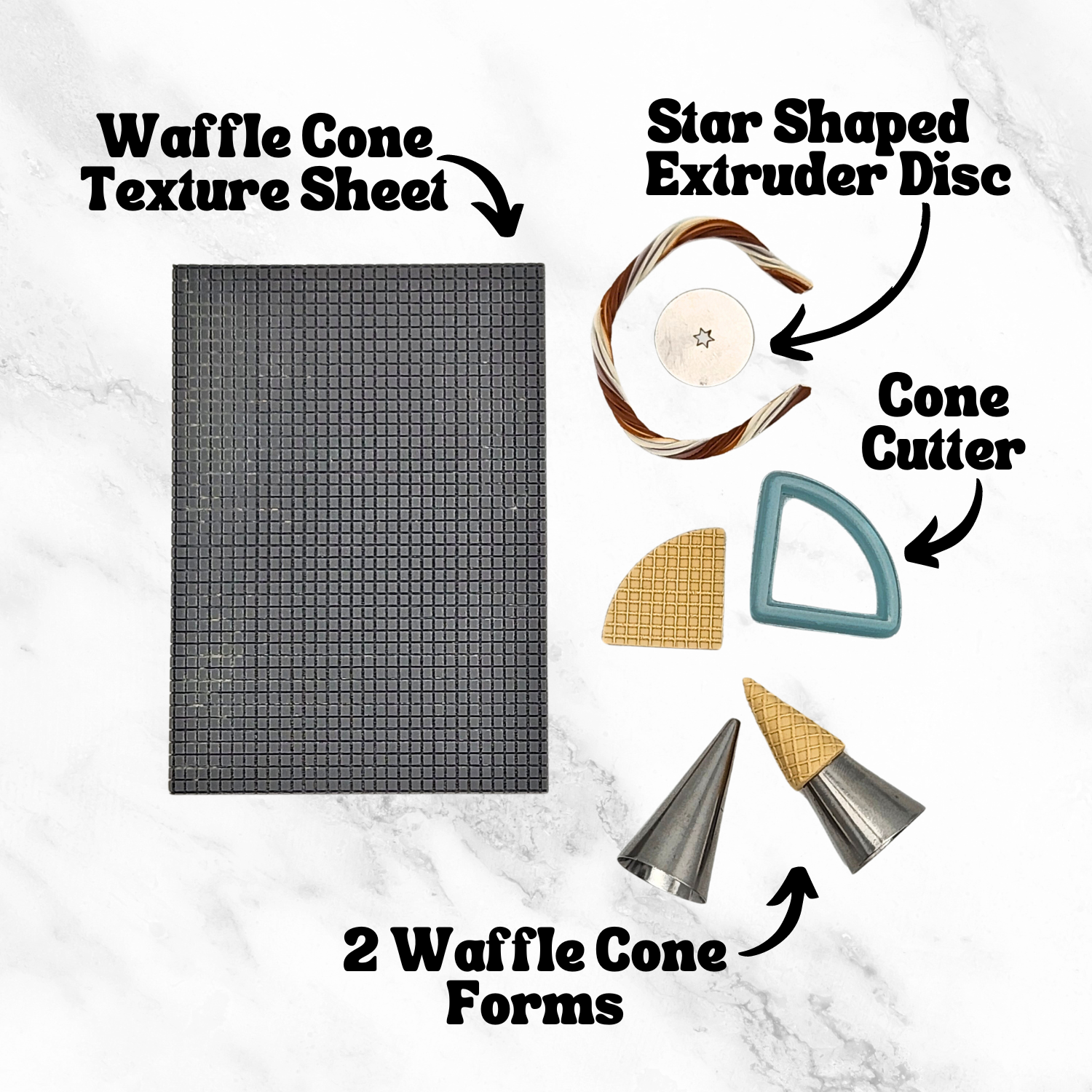

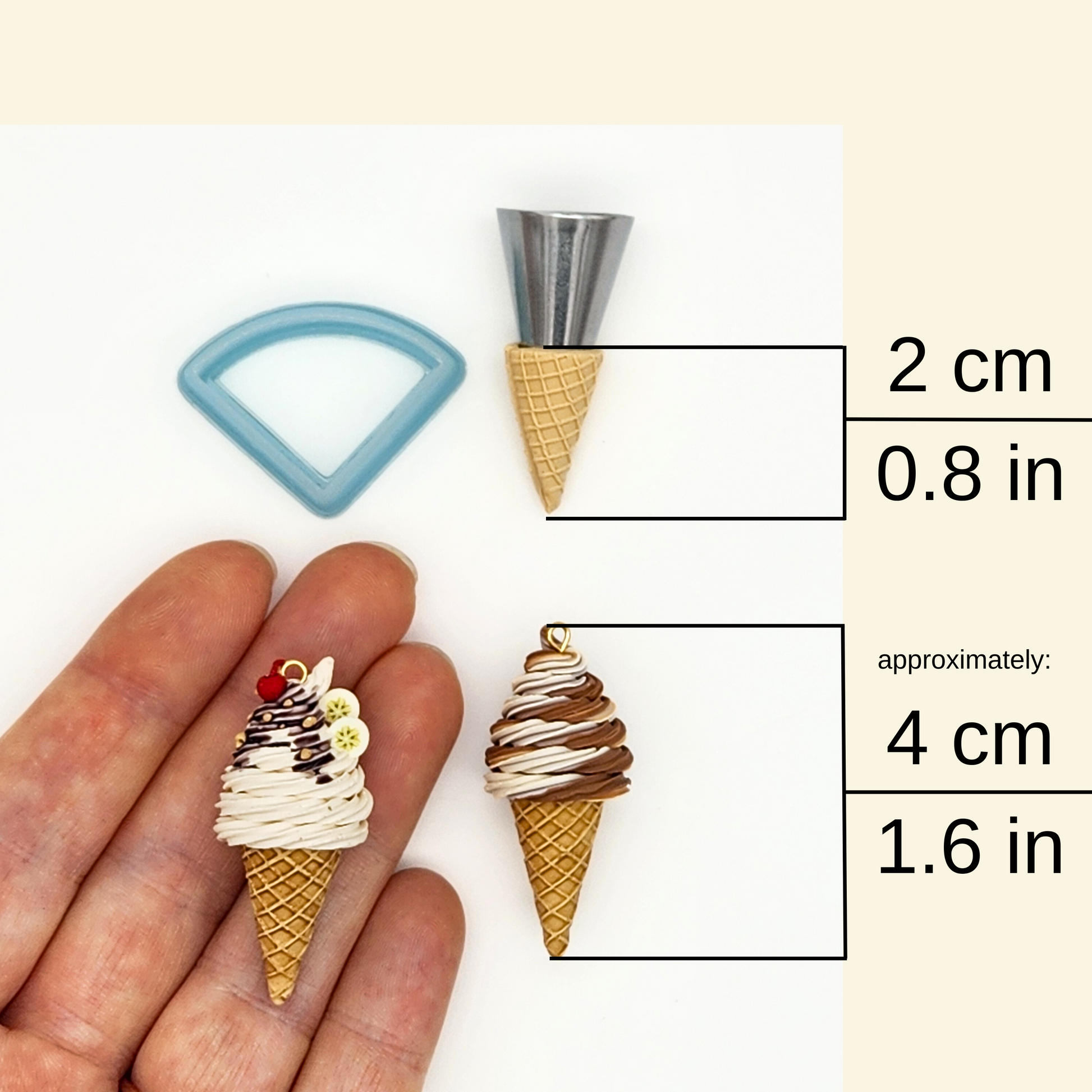

Create adorable 3D polymer clay soft-serve ice cream cones with our comprehensive kit! Each assembled ice cream cone stands approximately 4 cm tall, perfect for earrings! The full kit includes:

- Waffle Cone Texture Sheet: 7 cm x 10 cm (2.8 in x 3.9 in)

- Waffle Cone Clay Cutter: Quarter circle, 2 cm tall

- Star-Shaped Extruder Disc: Stainless steel, fits all standard polymer clay extruders (universal size 18.6 mm). Please ensure this extruder disk will fit your extruder before purchasing.

-

Waffle Cone Forms: Two small stainless-steel forms

- Additional waffle cone forms are available in packs of two.

Important: This kit requires a polymer clay extruder (not included).

Important: The extruder disc may bend slightly with use, especially with firm clay. This is normal and will not affect its performance.

Instructions:

- Roll out a thin clay slab.

- Impress the waffle cone texture sheet onto the slab.

- Use the cutter to cut waffle cones out of the textured slab.

- Optionally, add chalk pastel or other pigment to the waffle cone to add depth and create a more realistic look.

- Wrap the cone around the tip of the waffle cone form.

- Seal the pigment by brushing on a thin layer of translucent liquid clay.

- Bake the cone on the cone form.

- Let it cool after baking.

- Add oven-bake adhesive and scrap clay inside the cone, shaping the protruding clay into a base for the soft serve.

- If you plan to attach these ice cream cones to any metal findings, insert a kinked or looped eye pin into the scrap clay. The pin needs to be kinked or looped so that it won't pull out after baking. Leave a few millimeters of space between the loop and the top of the scrap clay.

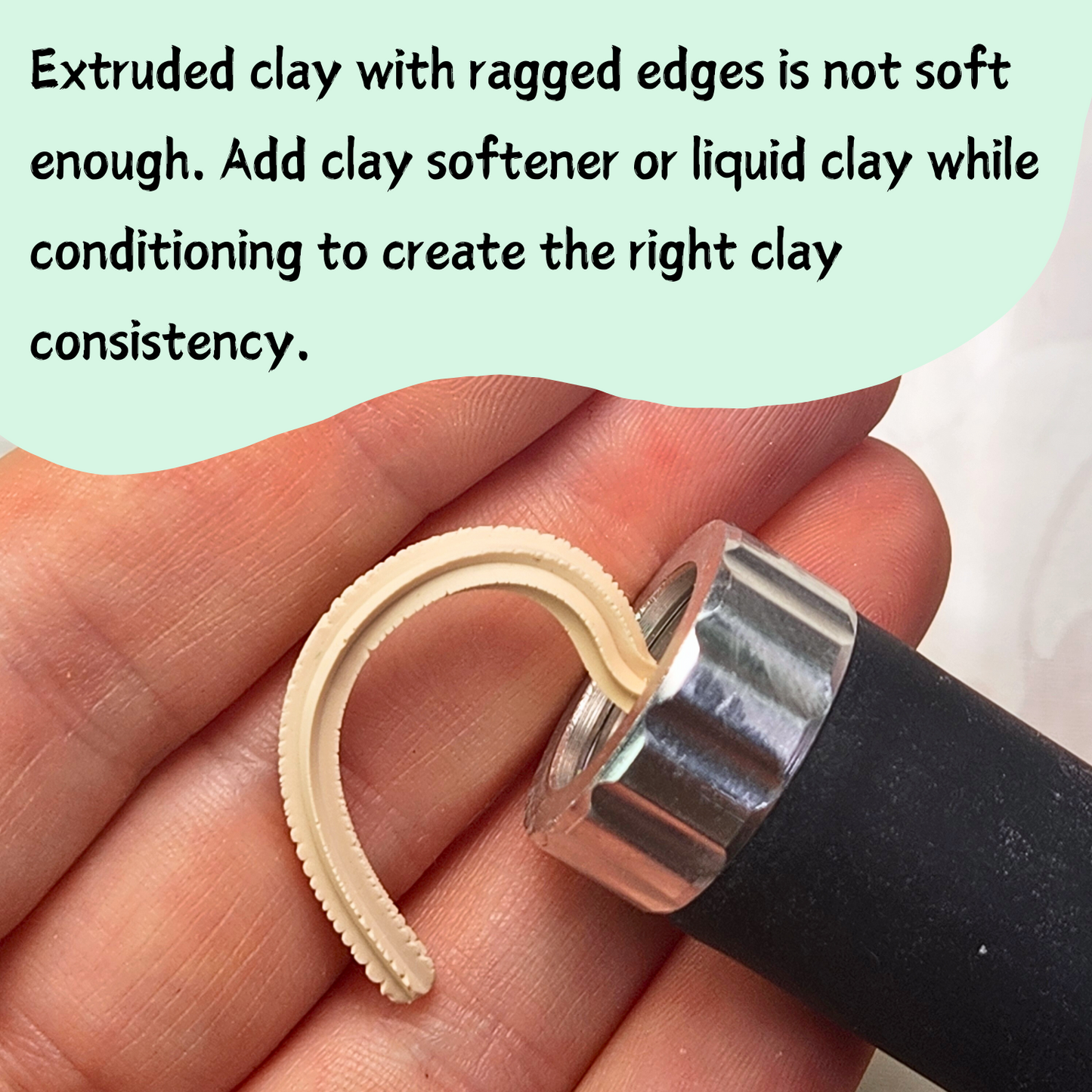

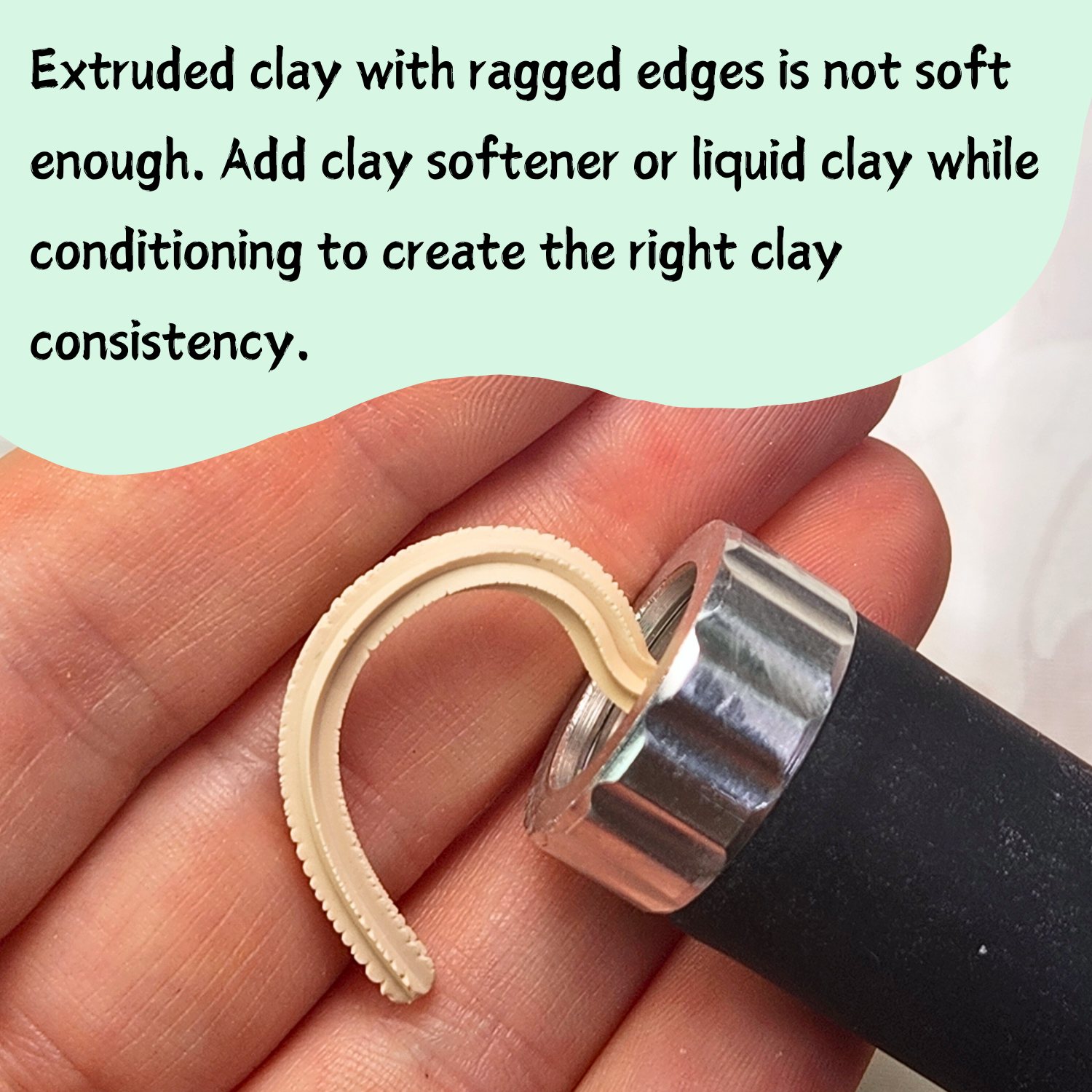

- Use the star-shaped extruder disc and extrude some clay into a long snake. Make sure the clay is very soft and well-conditioned. If the clay that comes out of the extruder is ragged, the clay is not soft enough. Add some clay softener or liquid clay and continue conditioning the clay until it's soft enough to extrude smoothly.

- Twist the star shaped snake of clay slightly, and begin to wrap it around the cone, starting where the waffle cone meets the scrap clay. You may find it helps to add a small amount of oven-bake adhesive to help the extruded clay stick to the scrap clay.

- Continue wrapping the clay around the cone, twisting as you go, to make a realistic soft serve.

- Once you get to the top, pinch the clay snake off and use your fingers to sculpt the tip of the clay snake into a point, so it looks like soft serve from a machine.

- Add whatever decorations you would like and bake the assembled ice cream cone.

To avoid squishing one side of your soft serve, you can drill some holes into a piece of wood to hold your cones while they bake. You can also gently lay the cones on a bed of cornstarch and bake them that way. The cornstarch rinses off easily after baking.

What is the recommended thickness of clay for using these cutters?

What is the recommended thickness of clay for using these cutters?

All of our debossing cutters are designed for use with clay that is approximately 2.5 to 3 mm thick. While outline cutters can be used with various clay thicknesses, smaller or more detailed cutters are generally easier to use with thinner clay.

What is the thickness of the cutting blade on your cutters, and how does it work differently compared to flat blades?

What is the thickness of the cutting blade on your cutters, and how does it work differently compared to flat blades?

The cutting blade on our polymer clay cutters features a precision 0.1 mm thickness. What sets our cutters apart is their beveled cutting edge design. This unique feature allows the cutters to slice through the clay, pushing the excess material out and away, rather than simply flattening it onto your cutting surface. As a result, you achieve crisp, clean edges with minimal to no need for additional cleanup or sanding, making our cutters some of the sharpest and most efficient on the market.

How do I prevent clay from getting stuck in the cutters?

How do I prevent clay from getting stuck in the cutters?

There are several factors to consider to ensure clay won't become stuck in your cutters: the cutting surface, the clay consistency, the thickness of your clay slab, and the release agent you use. Check out this article and video for a detailed description the techniques you can use to make sure clay won't get stuck in your cutters.

How long does it take to process and ship orders?

How long does it take to process and ship orders?

All our tools are made to order, and our processing time, or turnaround time, is up to ten business days. Please keep this timeframe in mind when placing your order, and we appreciate your patience as we craft your tools to meet our quality standards.

Can I choose the color of my cutters, or is it random?

Can I choose the color of my cutters, or is it random?

Unfortunately, we cannot guarantee the specific color of your cutters because we frequently experiment with new resin colors and shimmer effects. However, we assure you that regardless of the color, our cutters are always sharp and designed to look cute!

Are the cutter measurements exact, or do they have some variation?

Are the cutter measurements exact, or do they have some variation?

While our cutter measurements are approximate, you can expect them to be very close, typically within a millimeter or two of the posted measurements. We strive for accuracy and precision in our products.

Can I use these cutters for food preparation, or are they food safe?

Can I use these cutters for food preparation, or are they food safe?

We do not guarantee that our cutters are food safe. They are primarily designed for use with polymer clay and other crafting materials, so we recommend not using them for food preparation to ensure your safety.

Shop all Cutters for Creating 3D Crafts | Food | Summer | All Polymer Clay Cutters

View full details